Eagleview’s Bentley Systems to Co-Design Canada’s Keeyask Dam Project

Harnessing the innovation and technical expertise of the region, Exton-based Bentley Systems, in collaboration with Hatch Ltd, has created a new technology which can quickly and precisely compute the design options for the Keeyask Dam, a challenging and groundbreaking CAN$ 6.5 billion project in Manitoba in Canada, according to a staff report fromTenLinks.

The project is planning to make the Keeyask Generating Station at the dam a renewable energy source, generating close to 695 megawatts of capacity as well as creating an average of 4,400 gigawatt hours of electricity annually.

The energy produced will be incorporated into Manitoba Hydro’s electrical system for use in Manitoba and for export. As this is to be a concrete structure, the proper design and placement of its steel reinforcements is of critical importance.

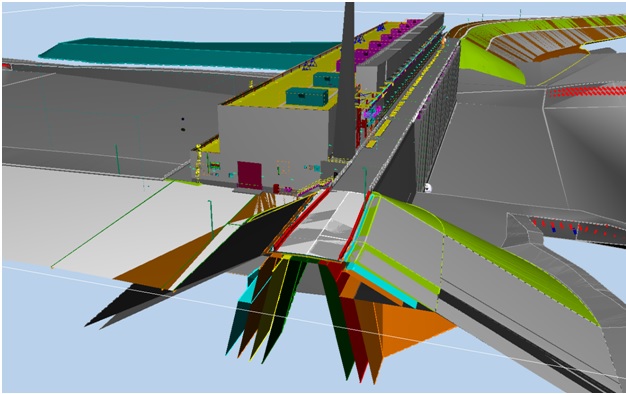

By using and tweaking Bentley Systems’ MicroStation for the project, Hatch modeled the inside of the draft tube as well as the center lines of the rebar along B-spline curves.

Every B-spline curve was made of anintricate chain of constant radius arcs and line segments. After splitting the bars automatically at 60-foot increments, Hatch used Bentley Systems’ ProConcrete to easily add rebar along the path.

“The complex shapes and sheer complexity of rebar placement in hydro projects made the design process more labor intensive with significant manual design and checking required,” said Charles McGowan of Hatch. “ProConcrete handled parametric standard rebar requirements quite well and automated this process considerably.”

ProConcrete and MicroStation were just two of the full range of Bentley software used by Hatch for this project, others key programs included its AECOsim Building Designer, Bentley Navigator, Bentley Raceway and Cable Management, gINT, ProjectWise, ProStructures, and STAAD. Hatch also used Bentley’s mobile apps such as ProjectWiseWorkSite, Navigator Mobile, and ProjectWise Explorer Mobile.

Use of 3D modeling on the project was extremely helpful, as it enabled the team to effortlessly manage any changes in the design as they were incorporated during the construction phase. In addition, using ProConcrete and including the contractors from the start of the project reduced the usual turn-around time needed to get approval for the detailed drawings.

Connect With Your Community

Subscribe to stay informed!

"*" indicates required fields

![95000-1023_ACJ_BannerAd[1]](https://vista.today/wp-content/uploads/2023/03/95000-1023_ACJ_BannerAd1.jpg)